1325 WOODWORKNGENGRAVING MACHINE

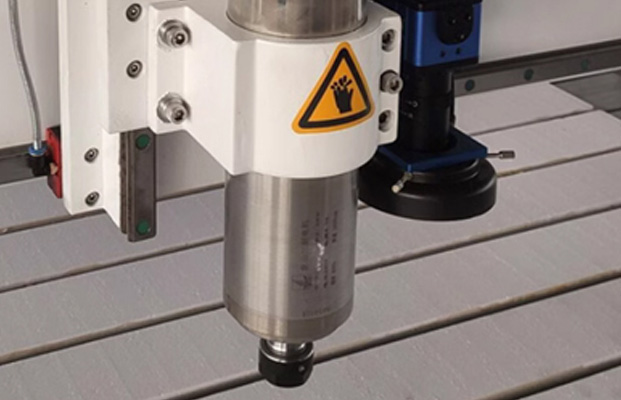

The Longtai woodcarving machine is a purpose-built piece of equipment engineered specifically for shaping and engraving wood materials. It leverages an array of cutting tools and specialized techniques to craft detailed patterns, artistic designs, and three-dimensional sculptures on wood surfaces.

Functionally, these machines offer dual operation modes: they can be manually controlled for more hands-on work, or they can be integrated with computer numerical control (CNC) systems. The CNC configuration enables highly precise execution of complex carving tasks, ensuring consistency and accuracy even for intricate designs.

English

English